Planning a Clean Room Project When you're planning a cl […]

Planning a Clean Room Project

When you're planning a clean room project, you'll likely be faced with many questions and challenges. The first one is how to qualify your bidders. You can do this by checking out their references and seeing whether or not they've completed similar projects on time and on budget. While references are not always positive, you'll have a much better idea of who to hire once you ask the right questions. Below are some tips to help you choose the right cleanroom company for your project.

The construction process is a major part of a cleanroom project, and it's crucial that you get the right team on board. Make sure that they have expertise in contamination control and cleanroom space planning, as well as with the materials of construction used in these projects. It's also helpful to include someone on your team who understands the material handling requirements and understands the requirements for storing and retrieving finished products. This way, you'll get the most out of your project and avoid costly mistakes that can negatively impact the entire process.

Your clean room project should include a gowning area that is isolated from the rest of the room by soft wall curtains. This is especially important in pharmaceutical and food processing, where it's vital to limit the amount of cross-contamination. When contamination is possible, it can cause product recalls, manufacturing shutdowns, and lost profits.

The location of the supply and return air grilles is a major consideration when planning your cleanroom project. Supply air grilles should be positioned low in the room, as this will enable them to simulate a "plug" flow. This will help keep high-potency products away from the operator. The air that comes into contact with product should be filtered before coming into contact with it.

Cleanroom software development processes consist of four core processes that are consistent throughout the project lifecycle. These processes include the project mission, schedule, risk analysis, training, and configuration management. You can also use incremental design for this process. The software development process will be much more effective when you follow these processes. You'll get a cleaner product faster, while keeping the cost of development low.

When building a cleanroom, there are two main options: modular cleanrooms and softwall cleanrooms. Both types have a steel or aluminum frame with vinyl curtain walls. These are easy to transport, and can be customized to fit any size. Both types offer good protection from contamination. The modular type is also less expensive. It can be reconfigured and is ideal for smaller projects. It's also a good option for temporary storage.

A properly designed air handling system can deliver filtered, clean air to your cleanroom and flush out any particulates that might be present. In a cleanroom, the air is normally recirculated through the air handling system. It is filtered to remove particulates and harmful gases. Typically, the air is also exhausted to the atmosphere. This ensures that the clean room is fully ventilated.

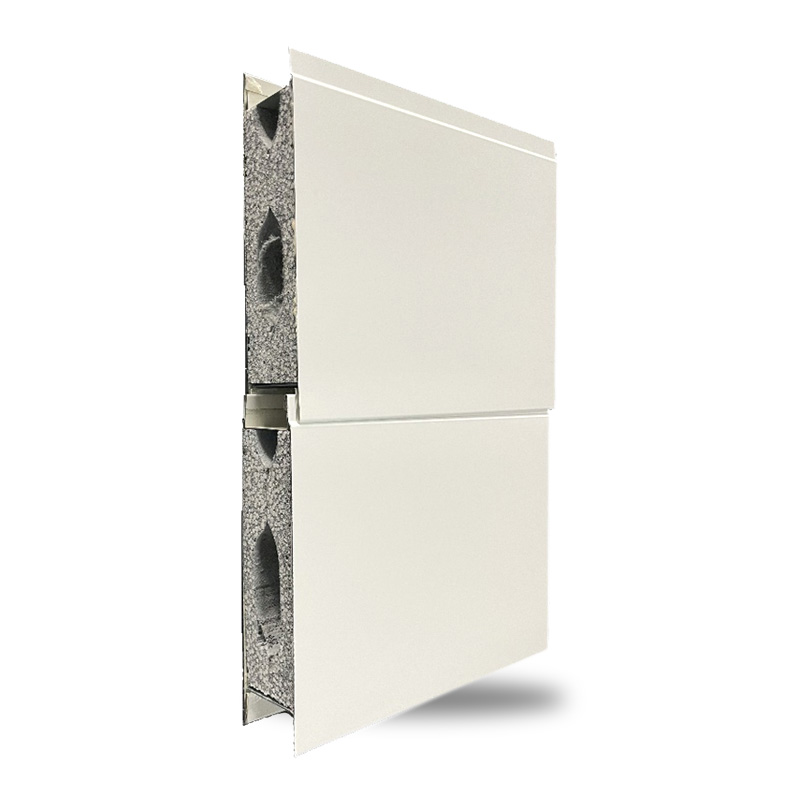

ROCK MAGNESIUM DRIFT BEADS FIREPROOF CLEAN PANEL

Rock magnesium drift beads fireproof clean panel is based on colorful coating steel as panel, fireproof rock magnesium drift beads as core material. By plating forming, glue, core material filling, composite repression and finished product palletizing and other process. By precise measurement and intelligent control to get a great promotion of the precision, strength, smoothness and beautiful degree of the clean panel, the product quality will more stable. Truly achieve "science and technology to make each clean boards look the same beautiful. Along with fast development of national economy in our country, especially the rapid growth of high-tech industries such as electronic semiconductor, biological pharmacy, food, medical, aerospace, scientific research, chemical industry and new energy in the last few years, the clean room is widely used in many industries, the fire rating of clean room purification panel attracts more and more attention from relevant government departments and industries.

The new national standard "Clean Workshop Design Code" (GB50073-2001) requires that the ceiling and wall of clean room (including core material) should be non-combustible, and shall not use organic composite materials; The fire resistance limit of the ceiling shall not be less than 0.4h, the fire resistance limit of the ceiling of the evacuation corridor shall not be less than 1.0h, and the fire resistance limit of the partition wall and its corresponding ceiling shall not be less than 1.0h. With the implementation of the new standard, higher requirements are put forward for clean room purification panels. Organic, toxic, poor fire performance sandwich panel will be eliminated.

Rock magnesium drift beads fireproof clean panels (modular), the wall thickness is 50mm and fire resistance limit is over1.5h. It is suitable for partition, ceiling system; rock magnesium drift beads fireproof clean panel is convenient installation and disassembly, and does not affect the main structure, and can choose different wall thickness according to different fire resistance grade in order to fully meet the requirements of fire prevention design. Compared with the traditional sandwich panel, they have good surface smoothness, good compressive strength, good flexure strength, environmental protection, high fire resistance rating. Especially suitable for clean room partition and ceiling, a big problem of the ceiling of clean workshop is solved, not only people can walk on it, but also can hole and wiring according to process layout .

Characteristics of Rock magnesium drift beads clean panel:

(1) Rigidity: rock magnesium drift beads clean panel is different from ordinary Portland cement solidification mechanism, it belongs to rigid cementing material, and does not harden in water.

(2) Mild to steel without corrosion: rock magnesium drift beads clean panel use magnesium sulfate as a moderator, it does not contain chloride ions and to steel without corrosion, so rock magnesium drift beads clean panel can replace magnesium oxychloride cement used in the field of fire door core material and exterior wall insulation board, and reduce the risk caused by chloride ion erosion of steel.

(3) High strength: after adding modified material, the rock magnesium drift beads clean panel adopts the arch structure, the strength is improved, the deformation is reduced, the compressive strength can reach 60MPa, the flexural strength can reach 9MPa, the bending strength can reach 4.16kn/m2, and it can be safely used for the wall, ceiling, partition and so on;

(4) Air stability and weather resistance: rock magnesium drift beads clean panel is air condensation material, only can continue to condense and harden in the air and it has good air stability. After rock magnesium drift beads clean panel is cured, the drier, the more stable.

(5) Light and low density: the density of rock magnesium drift beads clean panel is only 70% of ordinary Portland cement products, the density of products is generally 1600~1800kg/m³, and the density of cement products is about 2400kg/m3, rock magnesium drift beads clean panel has very obvious of Characteristics low density, light weight.

(6) Green environmental protection: no irritating and harmful gas release, smoke toxicity AQ1 for safety level, in line with fire safety, food safety and human body requirements.

Features of rock magnesium drift beads clean panel:

(1) Good fire performance: A1 grade combustion performance, the limit of fire resistance is 90min for 50mm metal surface rock magnesium drift beads clean panel.

(2) Good thermal insulation performance: the thermal conductivity is 0.056W/m· K, in line with the requirements of the national building code and has good thermal insulation performance, so the panel does not need to increase the heat insulation layer.

(3) Waterproof and moisture-proof: suitable for wet environment.

(4) Sound insulation effect is significant: sound insulation performance of 32DB.

(5) High strength: the compressive strength of rock magnesium drift beads clean panel is 60MPa, the flexural strength is 9MPa and the bending strength is 4.16kN/m2, which can be safely used for wall, ceiling and partition.

(6) Green environmental protection: smoke toxicity AQ1 meets the requirements of fire safety and human body.

(7) Light weight: the weight of 50mm metal surface rock magnesium drift beads clean panel is about 17kg/m2, which reduces the safety structural of the building and also brings handiness to installation and transportation.

(8) Smooth surface and beautiful appearance.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.