Clean room panels serve a crucial role in creating cont […]

Clean room panels serve a crucial role in creating controlled environments that are free from contaminants such as dust, airborne particles, microbes, and other pollutants. These panels are specifically designed to help maintain stringent cleanliness and sterility levels required in industries like pharmaceuticals, biotechnology, electronics manufacturing, aerospace, medical device production, and more. The primary purposes of clean room panels include:

Contamination Control: Clean room panels are designed to create barriers that prevent the infiltration of airborne contaminants and particulates from outside the controlled environment. This is essential in industries where even a small particle can compromise the quality of products or processes.

Cleanliness Classification: Different industries and applications require specific cleanliness levels based on industry standards. Clean room panels play a pivotal role in achieving and maintaining these cleanliness classifications by providing a controlled environment.

Microbial Control: In environments where biological cleanliness is critical, clean room panels help to minimize the presence of microbes that could impact the quality of products or experiments.

Process Integrity: Industries such as semiconductor manufacturing and pharmaceuticals require precision processes that can be disrupted by contaminants. Clean room panels ensure the integrity of these processes by providing a controlled and stable environment.

Product Quality: Clean room environments are essential for industries producing sensitive products, such as microelectronics, where even the tiniest particle can lead to defects or malfunctions.

Personnel Protection: Clean room panels contribute to protecting personnel working within these environments by minimizing the potential for exposure to harmful substances and by providing a controlled and comfortable working atmosphere.

Research and Development: In research environments, clean room panels create isolated spaces where experiments can be conducted without the risk of external contaminants affecting the results.

Regulatory Compliance: Many industries are subject to stringent regulatory requirements that mandate certain cleanliness levels. Clean room panels assist in meeting these regulatory standards and help avoid compliance issues.

Energy Efficiency: Modern clean room panels are designed to incorporate energy-efficient features, such as insulation and ventilation systems, ensuring a controlled environment without excessive energy consumption.

Flexibility and Adaptability: Clean room panels offer modular and customizable solutions, allowing for easy modification of the clean room layout, size, and configuration to adapt to changing production needs.

Reduced Construction Time: Compared to traditional construction methods, clean room panels can significantly reduce the time required to set up a controlled environment, leading to quicker project completion.

Cost-Effectiveness: While there are initial investments, using clean room panels can result in cost savings over time due to improved process efficiency, reduced product defects, and compliance with industry standards.

In essence, the purpose of clean room panels is to establish and maintain environments with controlled levels of contamination and cleanliness, ensuring the quality, safety, and reliability of products and processes in industries that demand high precision and strict regulatory compliance.

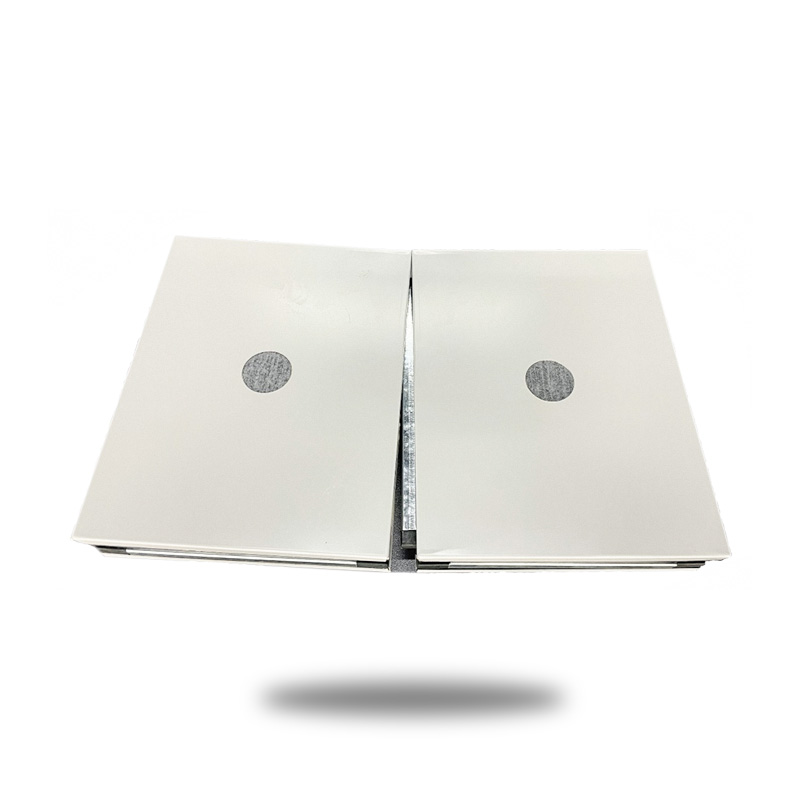

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.