Sandwich panels find applications in various industries […]

Sandwich panels find applications in various industries where lightweight, durable, and insulated construction materials are required. Some of the industries where sandwich panels are most commonly used include:

Construction and Building: Sandwich panels are extensively used in the construction of residential, commercial, and industrial buildings for roofing, wall cladding, partitions, and insulation purposes.

Cold Storage and Refrigeration: The excellent thermal insulation properties of sandwich panels make them ideal for cold storage facilities, refrigerated warehouses, and transportation vehicles such as refrigerated trucks and containers.

Aerospace: Lightweight sandwich panels are used in aerospace applications for interior paneling, cabinetry, flooring, and other structural components to reduce weight without compromising strength.

Automotive: In the automotive industry, sandwich panels are used for interior components, door panels, floors, and vehicle bodies to improve fuel efficiency and reduce weight.

Marine: Sandwich panels find applications in marine construction for boat hulls, decks, bulkheads, and other structural components due to their lightweight, corrosion-resistant, and waterproof properties.

Manufacturing and Industrial Facilities: Sandwich panels are used in the construction of manufacturing plants, warehouses, and industrial facilities for walls, partitions, and roofing to provide thermal insulation and structural support.

Regarding the effectiveness of insulation in sandwich panels, it largely depends on the type of core material used. Common core materials such as expanded polystyrene (EPS), polyurethane (PU), polyisocyanurate (PIR), and mineral wool offer excellent thermal insulation properties. These materials have low thermal conductivity, which means they can effectively reduce heat transfer through the panels, thus improving energy efficiency and maintaining comfortable indoor temperatures.

The effectiveness of insulation also depends on factors such as panel thickness, installation quality, sealing of joints, and the overall design of the building envelope. Proper installation and maintenance are crucial to ensure the insulation properties remain effective over time. when properly designed and installed, sandwich panels can provide highly effective insulation for various industrial and construction applications.

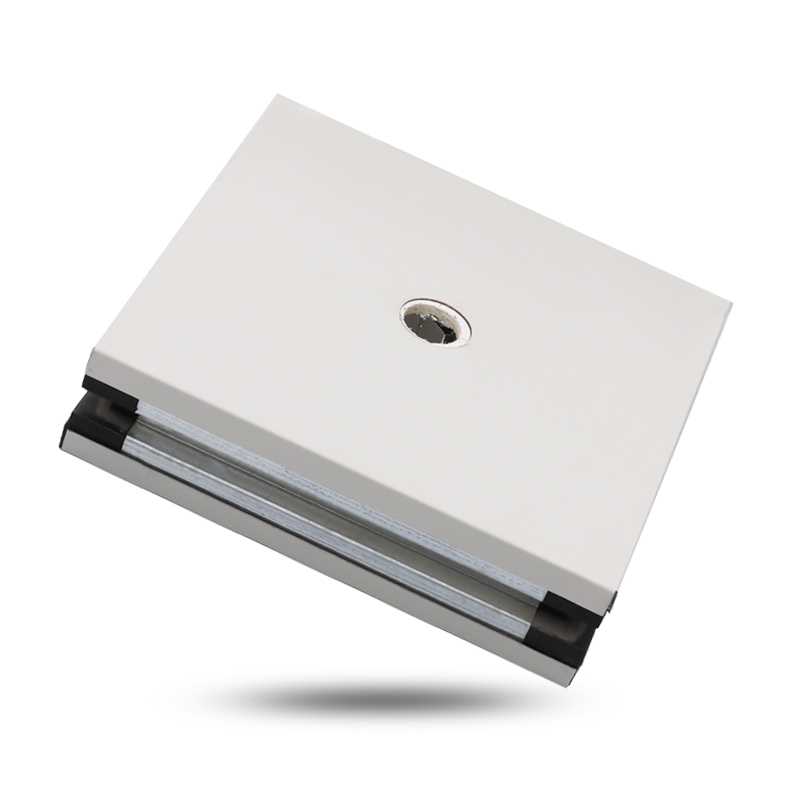

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.