Clean room doors are used in environments where air pur […]

Clean room doors are used in environments where air purity and temperature control are critical, such as in laboratories and manufacturing facilities. The requirements for clean room doors can vary depending on the specific application, but some common specifications include:

Air tightness: Clean room doors must be able to seal tightly to prevent the infiltration of contaminants. This can be achieved through the use of gaskets, weatherstripping, and other sealing mechanisms.

Positive pressure: Clean rooms are often maintained at a slightly higher pressure than the surrounding area to prevent contaminants from entering. The door must be able to maintain this positive pressure differential.

Smooth surfaces: Clean room doors should have smooth surfaces that are easy to clean and do not trap contaminants.

Low particle generation: The door and its hardware should not generate particles when in use.

Material: Clean room doors are typically made of materials that are resistant to corrosion, fire, and impact. Stainless steel, aluminum or PVC plastic are some of the common materials used.

Note that the requirements may vary depending on the clean room's class. Clean rooms are classified based on the number and size of particles permitted per volume of air, with Class 1 being the cleanest.

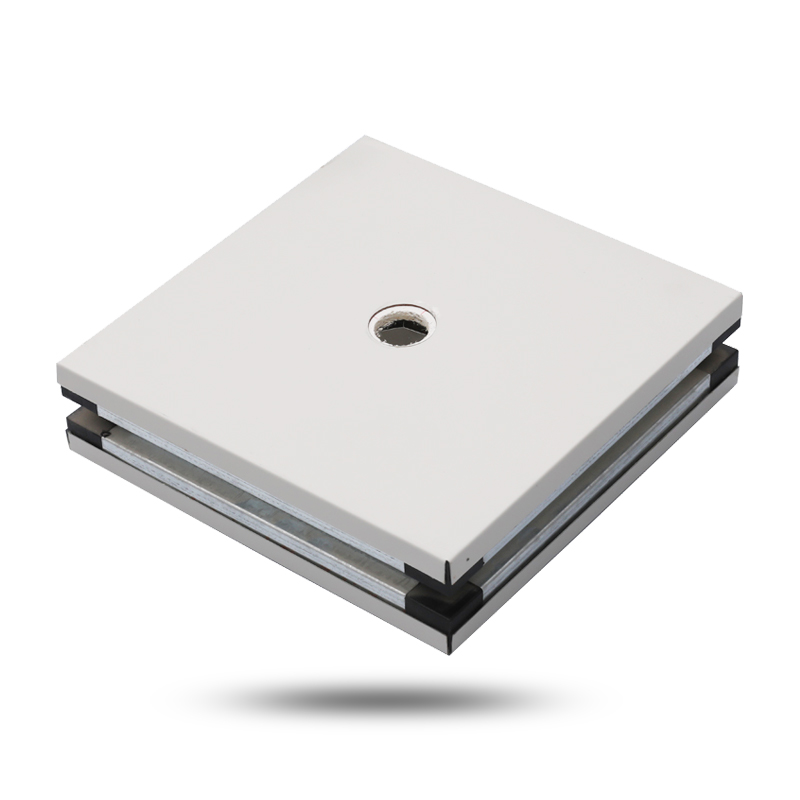

Structurer: Sandwich, 3 Layers

Surface Material: Anti-static Polyester Coated Steel Sheet

Thickness of Steel Sheet: 0.30mm-1.0mm

Core Material: Polyurethane Foam

Density:30-45kg/m3

Zero Formaldehyde Emission

Width:982mm/1182mm, Length: customizable not exceed 10meters.

Advantage: No-dust accumulation and Self-clean, Water resistant, high strength& durable, Eco-friend.

Our new models offer superb design;competitive prices and their new features give them distinct advantages over similar products from other manufacturers.